Offset Printing Vs. Digital Printing

Have you ever wondered how those beautiful brochures you hold in your hand get produced? Or how those flyers, folders, and postcards come out crisp and shiny?

Printing is a complex process made up of several steps. A lot goes into those pieces we hold and admire–finishes, stocks, sizes, cuts, folds, binding. It’s as much a craft as it is a science. It takes a team of experts paired with the right equipment and technology to get the job done and done right.

Here at Fineline, quality is reflected in everything we do. Our experts lead the way in crafting custom print solutions that fit our clients’ needs.

When it comes to printing, there are two main types: offset and digital.

What’s the difference?

Let’s look into it a little further:

Offset Printing

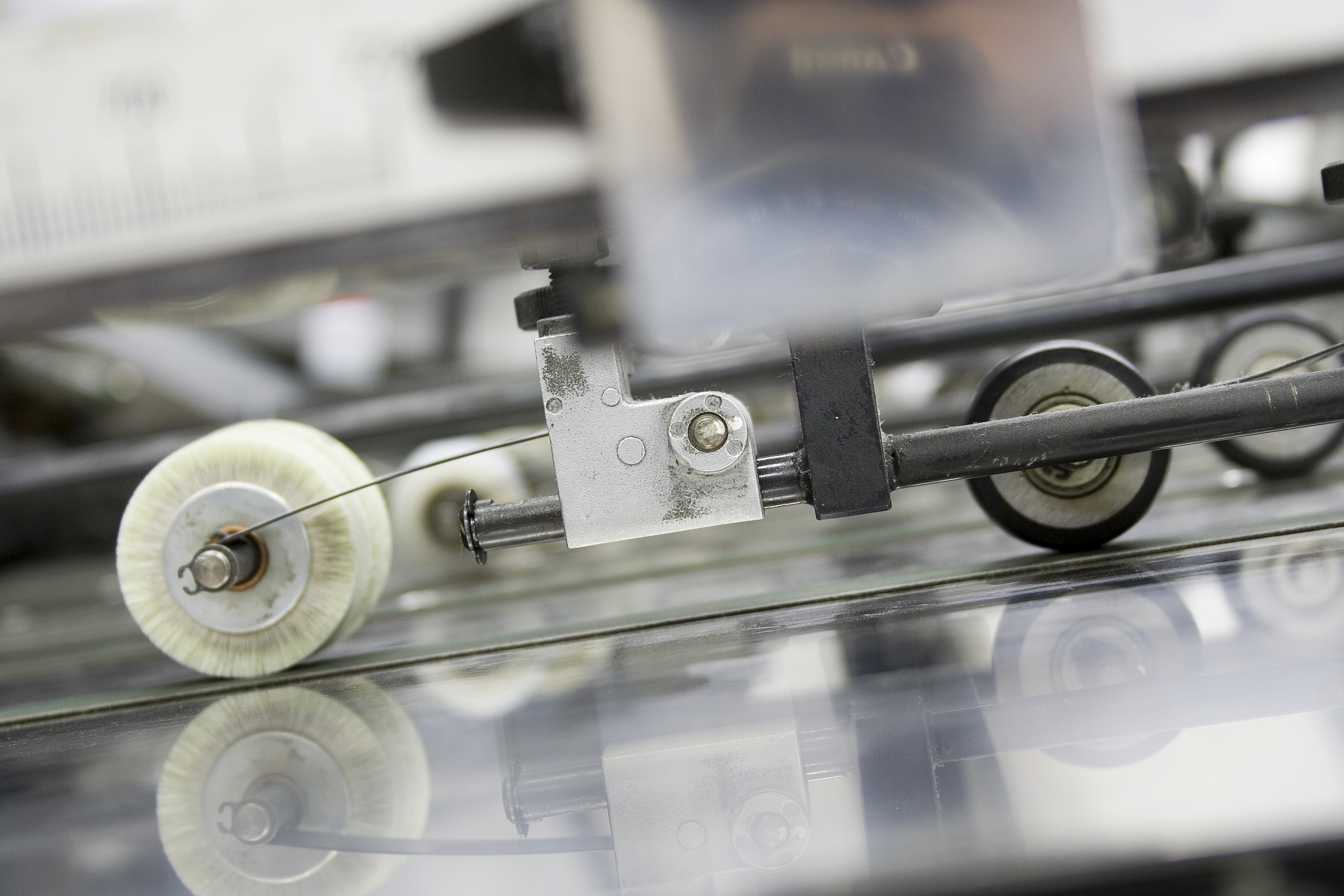

Offset printing, also called lithography, uses plates to get the job done. The plates are typically made from aluminum. Art and text are put on the plates which are dampened by water and ink via rollers on the press. The ink adheres to the image area and is then transferred to a rubber cylinder. The ink and image are transferred to paper as it passes around the cylinder.

It’s called offset printing because the image is not directly transferred from the plates to paper. Instead, it’s offset to a rubber cylinder which transfers the image.

There are quite a few advantages to offset printing:

- Large quantities printed at lower costs

- Many different types of paper and stock options

- Many different types of inks and colors

- Highest possible printing quality

Digital Printing

Digital printing uses toner to get the job done. It’s best for lower quantities. It’s also great for jobs with variable data. It’s practically the only option to use when a piece might have any customized data. It allows for an easier setup and management. You plug in the data and images onto the computer and transfer them straight to the printer to produce the product you want. It’s much more cost effective than offset printing which requires intensive setup and production to yield the final product. In many cases, you can create the final product via one pass through a digital printer vs. offset printing which requires several different steps and sometimes several different machines to get the final job done.

It’s the best solution for smaller run, lower quality projects.

Advantages of digital printing:

- Setup costs are lower for short runs

- Print on demand

- Lower minimum quantities

- Inexpensive black and white

- Variable data

- Technology is improving quality

Digital printing doesn’t require plates to be changed. This saves on cost and time. The trade-off? You lose some of the quality and attention to detail that plates provide. The most popular methods of digital printing include inkjet or laser printers. It’s all digital, versus the more manual route of offset.

The Fineline Difference

Our experts make all the difference here at Fineline. They combine their knowledge and experience to craft custom solutions for our clients.

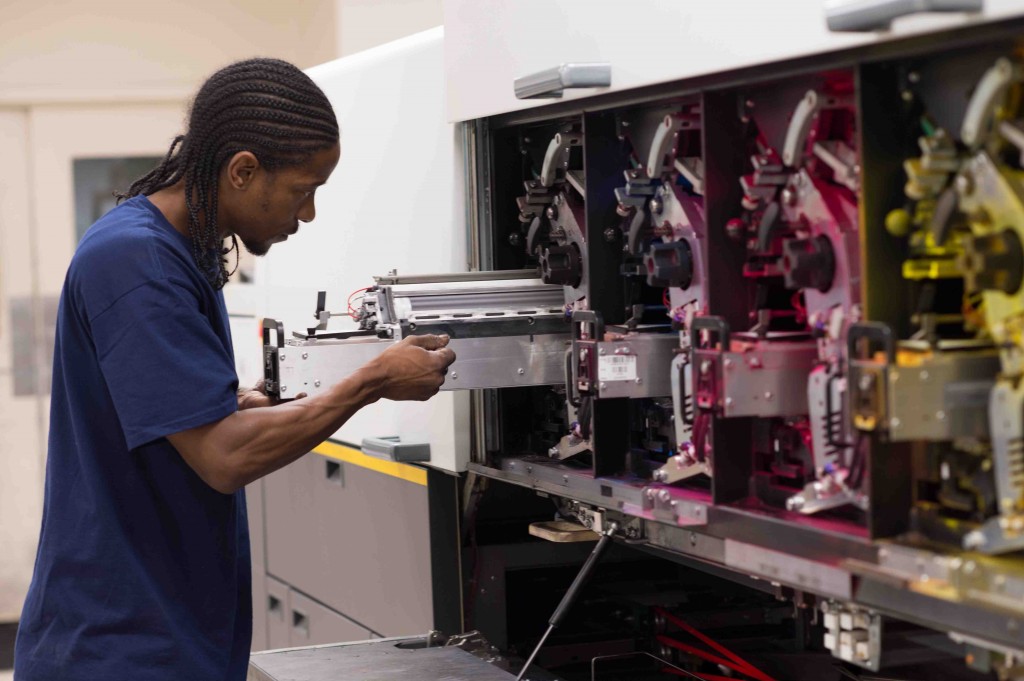

The Fineline experience begins with one of our CSRs taking a consultative approach and tries to get a sense of the entire scope of the project to guide the client to an understanding of what they might need. When it comes to our offset and digital printing capabilities, Angie notes that Fineline’s equipment makes a difference. Fineline has both small and large full-color offset presses, not to mention the other machinery we have in our building. That diverse array of equipment allows Fineline to offer a large range of custom solutions to clients under one roof. We’re flexible.

Fineline’s estimating gurus look at the project from a technical angle. This brings knowledge and experience to help design the best possible way to produce a product that achieves the desired results. They note one of the things that makes Fineline different is that the entire team brainstorms and consults with the client through the whole process. That synergy helps Fineline maximize the solutions it provides.

Rick Kappel, our Director of Engineering, helps manage estimating and many different aspects of our print operations. He recognizes that print technology is always evolving and notes that as one of Fineline’s advantages–we keep ahead of emerging trends. From print tech to our in-house IT team, Fineline is innovating in as many ways possible to offer competitive, comprehensive solutions for clients.

Our pre-press technicians help provide proofs quickly to ensure the job will be done right.

Our press operators manage the craft and chemistry of the different jobs to produce the best possible product.

Our shipping personnel work hard to deliver products to the end client at the right time.

As you’ve gathered, a lot goes into printing. Whether it’s offset or digital, one thing holds true: experts make all the difference.

Our team of experts make the Fineline difference.